We use cookies to give you the best possible experience. To accept cookies continue browsing, or view our Cookies Policy to find out more.

How Duvets & Pillows Are Made

Duvets and pillows, we all use them and, hopefully, we all get a good night’s sleep with them. But have you ever wondered what goes into making duvets and pillows? Well, you no longer have to wonder, as this article focuses on everything that goes into constructing duvets and pillows before it ends up gracing your bed. Let’s begin!

What is Duvet Casing?

Before we begin, it’s a good idea to understand what is meant by duvet casing and why it’s important to duvets. Put simply, duvet casing refers to the fabric that holds in the filling of the duvet.

A duvet casing should be tightly woven to stop the small fibres or the smaller clusters of down that may be inside from escaping through the small gaps between the yarns in the weave. It should be comfortable and absorbent to allow the body to breathe, as well as being down proof to prevent leakage of the duvet filling.

Cotton is the most popular material to use for duvet casing, as you’ll see with many of our own duvets, but polyester/cotton blends are often used too.

The type of fabric used for duvet casing tends to be either dobby, jacquard or percale.

- Dobby is a finely woven fabric, which can be either plain or featuring a decorative pattern that can be anything from geometric shapes to flowery patterns.

- Jacquard refers to more elaborately woven fabrics that have raised embroidered or embellished areas. It’s an old-fashioned technique that comes from being produced on a jacquard loom.

- Percale is a plain-weave lightweight fabric that has a smooth finish and a crisp feel, which makes it ideal for a fabric that’s going to be against your body all night long. It can be made from both combed and carded cotton yarns, which you can learn more about in this part of our ultimate guide to cotton fabric manufacturing.

How Are Duvets Made & What Are The Types Of Duvet Construction?

There are two main types of duvet construction that we’ll cover here; sewn through construction and cassette or box construction. Let’s start with sewn through.

Sewn Through Duvet Construction

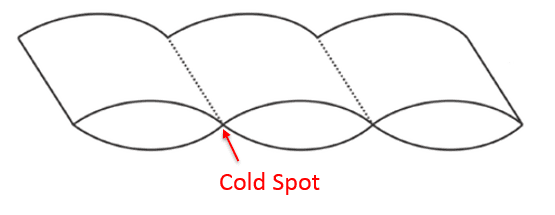

On a sewn through duvet the stitch is sewn from the front right through to the back of the duvet to form channels, squares, or diamonds to keep the duvet fill in position. Channels give the filling more freedom to move within the casing.

However, the downside with a sewn through duvet is that the areas where the duvet is stitched through form cold spots. That’s because there is no loft and therefore no air trapped in this area to provide insulation, so these areas will let heat out.

To make a sewn through duvet the filling is laid out between the top and bottom of the casing fabric and clipped on to the sewing machine, which pulls it flat.

The machine can have either a single needle or multi needles sewing at the same time. The machine can have a single needle or can have multi needles sewing at the same time. The picture above shows a single needle machine.

The needles are programmed to pass over the duvet and sew in the channels, or whichever pattern is required. Common duvet patterns include boxes, diamond shapes, waves etc.

For feather and down, the fill is blown into pre-hemmed casing. The filling is then beaten on a machine to even it out before it is stitched.

Overall, making a sewn through duvet is quite a straight-forward process and is less expensive to produce than a cassette duvet.

Cassette/Box Duvet Construction

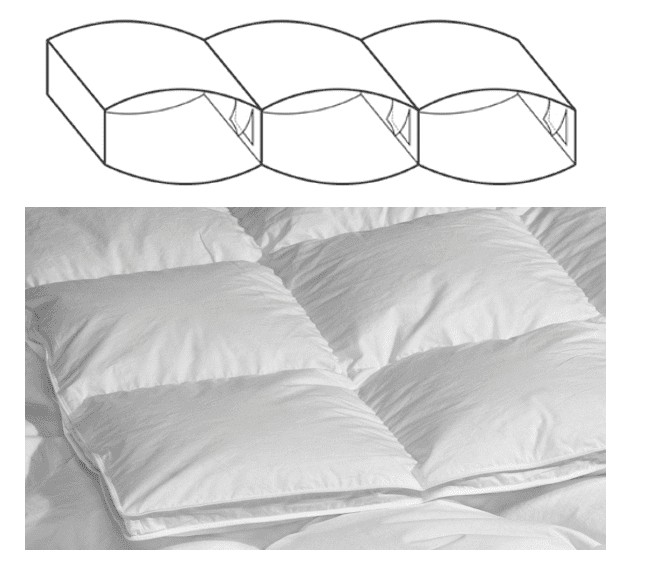

A cassette or box duvet construction is generally reserved for use on higher quality duvets. This method is made up of a series of sealed and walled rectangular pockets that keep the filling evenly spread throughout the duvet when it’s in use. It isn’t stitched from front through to back at any point, ensuring that cold spots don’t appear.

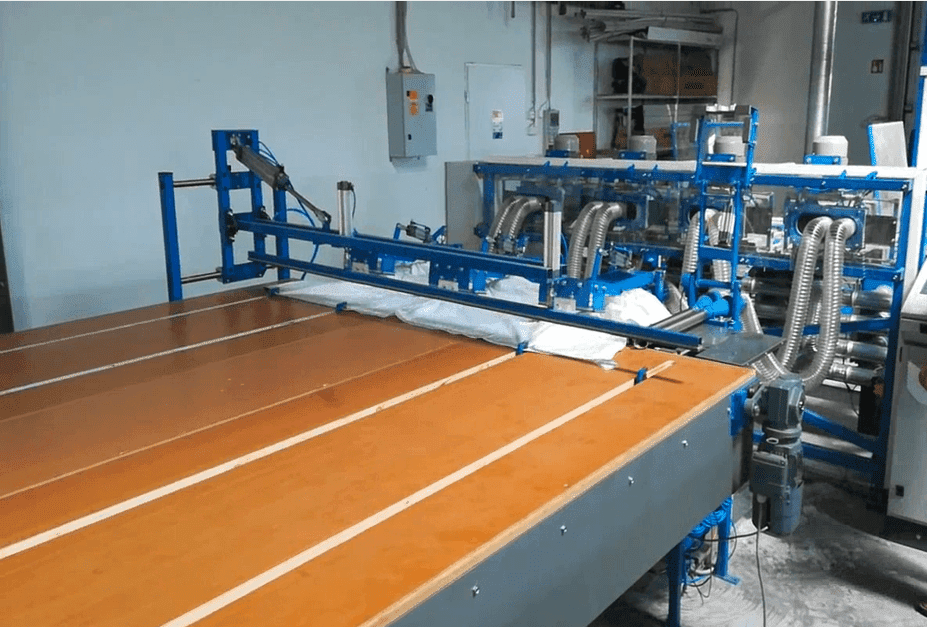

Filling a duvet with a cassette construction is a bit more complicated than sewn through duvet construction.

A special machine is required to carry out the duvet construction, which consists of a series of tubes to blow the filling into each of the individual chambers in the duvet. You can see an example of the machine in the image above.

As this machine is more complex, it’s more costly to buy and run for the manufacturer. It also takes more time and effort to fill the duvet, with both these issues making it more expensive to produce. This is why cassette or box duvet construction duvets are more expensive to buy for the customer, but you do get the added benefit of a higher-quality duvet that will last longer.

How Are Pillows Made?

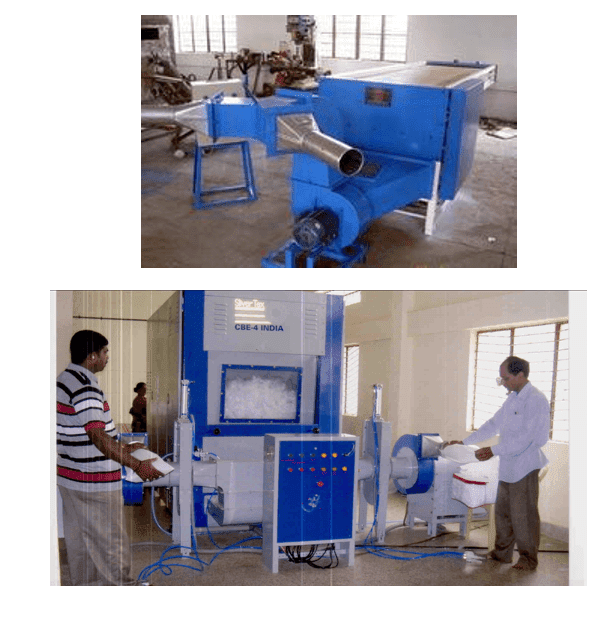

In the case of pillows, the filling is usually blown into the hemmed pillow tick by a machine.

The machines themselves can vary in complexity, as seen in the two photos above. The pillow is filled with the fill weight needed to meet the specification.

Alternatively, pillows can be stuffed by hand. This is often the method use for synthetic fill. The filling is stuffed into the pillow and weighed on sales until the it reaches the correct weight.

Edging Duvets & Pillows

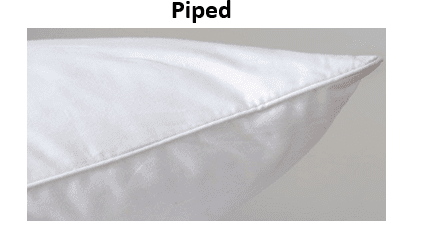

When it comes to stitching the edges of the duvet or the pillow, there are several different stitch types. The most common stitches tend to be overlock, bound edges and piped edges depending on the quality needed.

The overlock stitch is widely use, particularly on duvets. In this method the thread is sewn over to seal the 2 edges of the duvet. This is the least expensive method, but the stitch can become untidy and unravelled over time.

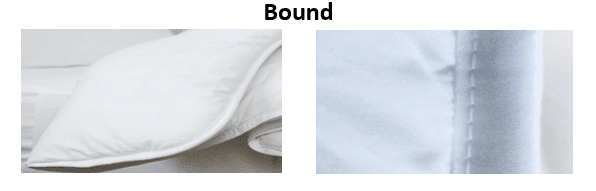

Bound edges stitching is where the edges are held together in a separate strip of fabric that’s folded over the two edges and sewn as you can see in the picture above. This gives a very neat edge, but it’s a bit more expensive than overlock as there’s more work involved.

Finally, a piped edge is often used on a higher-end product to give a more refined, high-quality finish. To create the pipe, a strip of folded fabric is sewn into the seam. Alternatively, the edges can be stitched around a cord to form the pipe. This gives a neat classic finish but, of course, it’s more expensive!

Now that you know what goes into making pillows and duvets, why not take a look at our high-qualtiy duvets or our super-snug pillows?

If you'd like to know how bedding in general is made, take a look at part 6 of our ultimate guide to cotton fabric manufacturing.